About FX3D

FX3D provides precise 3D printed fixtures to measure your parts quickly and accurately within allowable tolerances. Utilizing inhouse engineering we create Go-No-Go fixtures from customer furnished data. Using proprietary inspection software we certify the fixture to the solid model. FX3D is an ITAR regulated and NIST compliant company.

3D Printed Fixtures

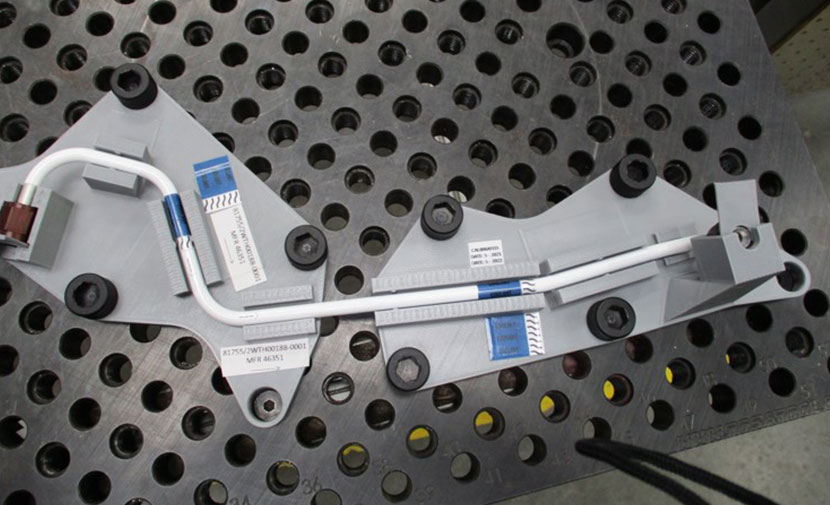

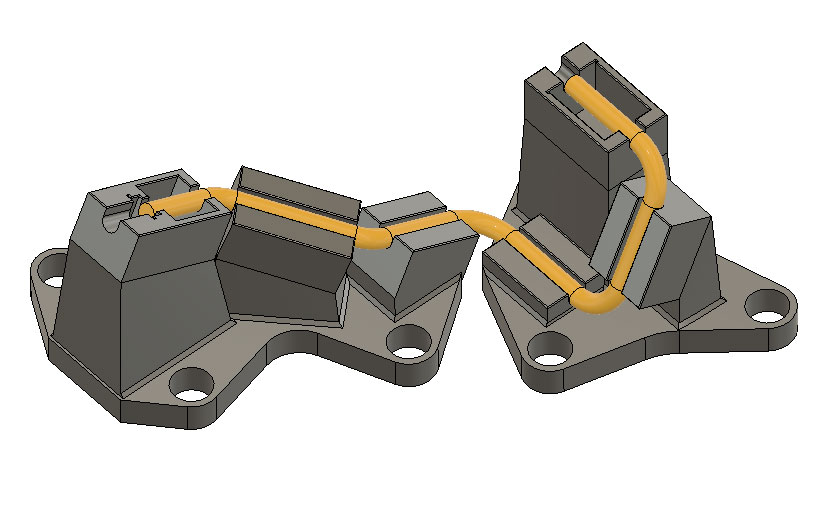

- 3D printed fixtures are being used to: Increase Efficiency, Dimensional Accuracy, Identify Marking Location and Part Orientation.

- Internal work instructions are written and approved for: Design, Printing, Usage and Inspection.

- Fixtures are used at Final Inspection and/or Source Inspection buyoff for Fit, Form, and Function.

- Our process and fixtures are approved by many customers for new production parts as well as legacy programs including: Lockheed Martin, Northrop Grumman and Collins Aerospace.

- Our 3D Fixtures include reference lines to mark end of part for fast fabrication

Fixture Storage

Fixtures go through rigorous inspection and break down to small container size saving on valuable storage space.

Fixture Inspection

Propietary inspection software measures 3D printed fixtures and compares it to the model data with accuracy to (+/- .0005)

CMM inspectedTolerance +/- .010 | Quick Turn | AS9100 | ISO9001 |

BUILT FROMSolid Works | CATIA | STEP | IGES | XYZ |